Doesn’t lean ever get tedious? Does it ever change?

Lean was born of the discovery in the late 1980s that Toyota outperformed all its competitors in all dimensions – not just one, but all. Thirty years later (30!) Toyota is still outperforming its competition whilst having produced the single most revolutionary innovation in the auto industry: the gas-electric hybrid.

No, lean doesn’t get boring, because two huge mysteries remain unsolved.

The first one is how does Toyota do this? It has a method, it shares method, in the form of the Toyota Production System and the Toyota Way and other stuff – but do we really understand this? We now know that they’re not doing what the other are doing but better – they’re doing something else, which is hard to grasp (even for Toyota’s own hirees when they’ve first experienced at traditional business model).

The second one is how hard so many companies are claiming that lean doesn’t need to refer to Toyota but take their own version of “lean” instead. They’ve got it” – forget Toyota, follow our bastardized “So-and-so excellence system.” I’d happily do so if they had the same consistency of outstanding results as Toyota still does. Why not just continue to try to figure out what Toyota does and what lessons this has for us? Mystery.

Personally, I can say that my curiosity about what Toyota does different (it does plenty the same, it’s just another car company) is still strong. I’d really like to figure it out.

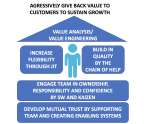

So my understanding of lean changes. Currently, I see the TPS as:

- Aggressively give back value to customers through Value Analysis and Value Engineering topics in order to improve safety, quality, lead-time, costs, morale and energy performance

- Build quality into every technical process by establishing a chain-of-help for frontline workers and treat all defectives and rework problems as they occur, on the job

- Increase flexibility in the delivery chain through just in time techniques, and most notably pull closer and closer to take time to see the gap with perfect one-piece-flow on demand

- Engage teams in owning and changing their own ways of working by feeling greater responsibility for their delivery (through Just in time and built in quality) and by deepening their confidence in their skills working with work standards and standardized work.

- Build on a foundation of mutual trust by looking at happy/friendly teams as the basic bricks of the organization and doing what needs to be done to develop their own sense of ownership of their workplace (5S) and creating real enabling support systems (TPM)

And, yes, I agree, I need to re-focus on heijunka to link the Just-in-time tension with team work stability. It’s a system and our understanding is never quite complete.

Almost 25 years studying this system – and it’s like peeling an onion: every time you take a layer off, there is a deeper one underneath.

But, personally, I find that the most exciting and engaging part of trying to figure out what Toyota does is that their leadership continues in showing us how to solve environmental problems. Their goals in the matter are simply astounding, as show Kelly Singer and Steve Hope:

The more you learn, and the more you experiment at the gemba, the more you discover there is not learn. So, no, lean doesn’t get tedious, and no, the basics don’t change – our understanding of it does.